5 Technologies for automating your manufacturing processes

Light manufacturing SMEs are those small to medium sized businesses that cover a broad range of sectors. Small scale production of textiles & apparel, metal fabrication & machining, jewellery, leather goods and many, many more products fall under the “Light manufacturing” umbrella. It is these smaller scale businesses that can miss out on technological advancements, or naturally assume that brand new tech is reserved only for the giants of industry. This is simply not the case, as we put to you 5 simple technologies that can help light manufacturing businesses up their tech game and cut down lead times:

- Augmented Reality (AR):

AR is the halfway point between Virtual Reality (VR) and the real world. AR overlays digital information onto the physical world, using devices such as mobile phones, tablets and VR headsets. This provides real-time data and instructions to operators on the shop floor. It enhances human-machine interaction and aids in complex assembly processes.

Use case

Furniture Manufacturing: In the production of customized furniture, AR can be integrated to guide craftsmen through the assembly process. The AR system overlays instructions on intricate woodworking tasks, ensuring precise assembly and assisting artisans in creating bespoke furniture pieces.

- Industrial Internet of Things (IIoT):

IIoT refers to the network of interconnected devices and sensors embedded in industrial machinery and equipment. These devices collect and exchange data, facilitating real-time monitoring and control of manufacturing processes. These range from Torque controls built into power tooling, smart cameras controlled by mobile apps, and even humidity sensors for automated irrigation systems.

Use case

Textile and Apparel Production: Within the textile and apparel sector, IIoT sensors are embedded in knitting and weaving machines. These sensors monitor equipment conditions, detecting potential issues and optimizing machine performance to maintain high-quality production in the fast-paced fashion industry.

- Artificial Intelligence (AI) and Machine Learning:

AI and machine learning involve the development of algorithms and systems that enable machines to learn from data and make decisions without explicit programming. In manufacturing, AI can analyze complex data sets and optimize processes.

Use case

Food Processing: In the light manufacturing of food products, AI is applied to quality control. Machine learning algorithms analyze visual data, in what is sometimes referred to as “Machine Vision”. This is used to identify irregularities in packaging and ensure adherence to quality standards. This enhances the efficiency and reliability of quality control processes in the food industry.

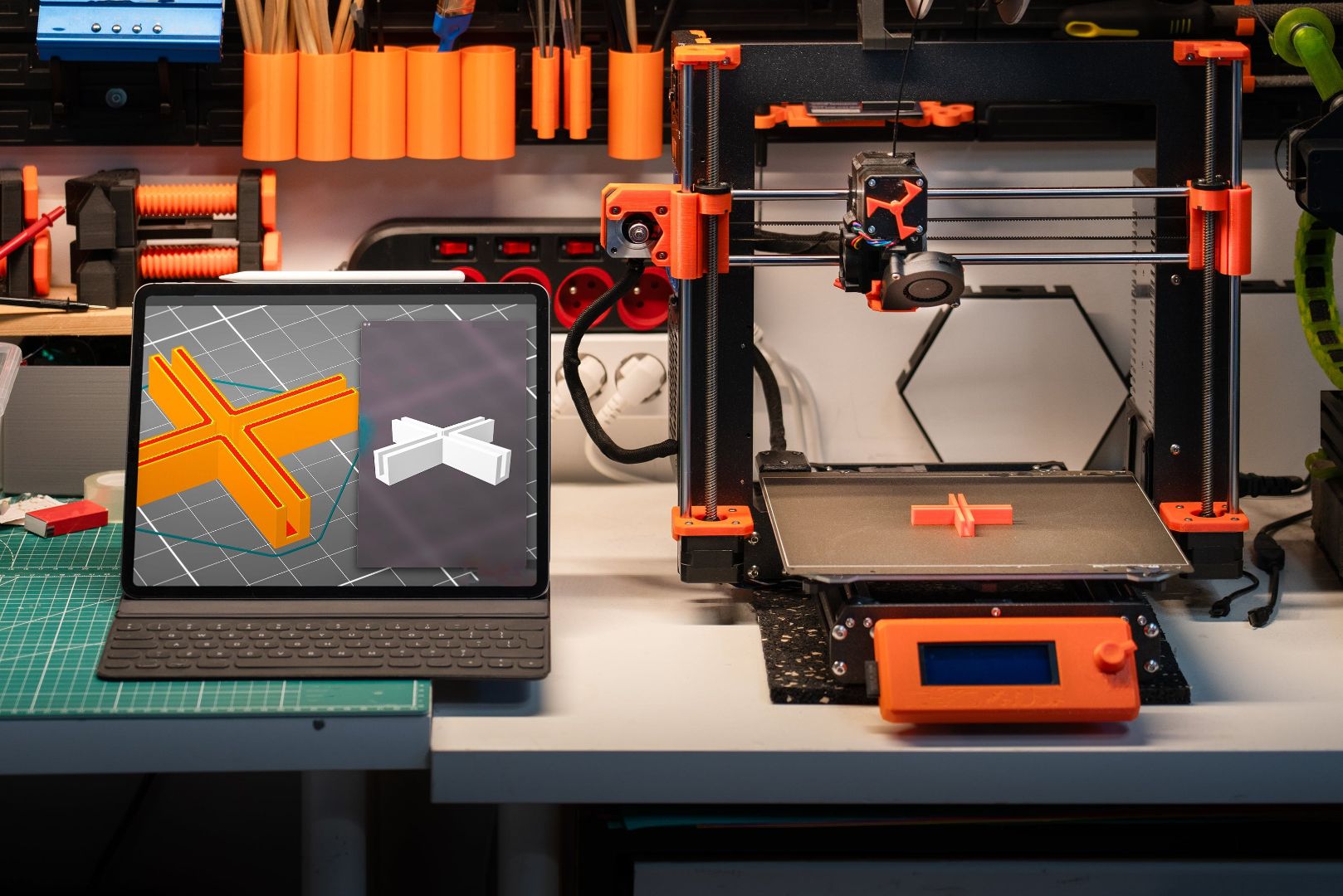

- 3D Printing (Additive Manufacturing):

Description: 3D printing, or additive manufacturing, builds objects layer by layer from digital models. This technology allows for the creation of complex and customized components with reduced material waste.

Use case

Toy and Game Manufacturing: Within the toy and game manufacturing sector, 3D printing is employed for rapid prototyping of new toy designs. This allows designers to quickly iterate and test different concepts before moving to mass production, facilitating creativity and innovation in the industry. Some smaller businesses support themselves with 3D printing alone, as some machines can use a wide array of materials, including recycled plastics and plant based resins!

- CPQ Software:

Configure Price Quote (CPQ) systems allow for the dynamic configuration of products based on customer requirements. CPQ systems enable accurate and dynamic pricing based on various factors, including product features, quantities, and customer specifications, thus streamlining the generation of quotes for customized products. This allows the customization of products based on customer preferences.

Use case

Jewellery Manufacturing: In the production of custom jewellery items, CPQ software, such as Multiverse is utilised to configure pieces based on customer preferences. The software considers market prices of precious metals and gemstones, dynamically pricing each custom design. This ensures accurate quotes for bespoke jewellery, enhancing the customer experience in the luxury goods sector.

15 January 2024